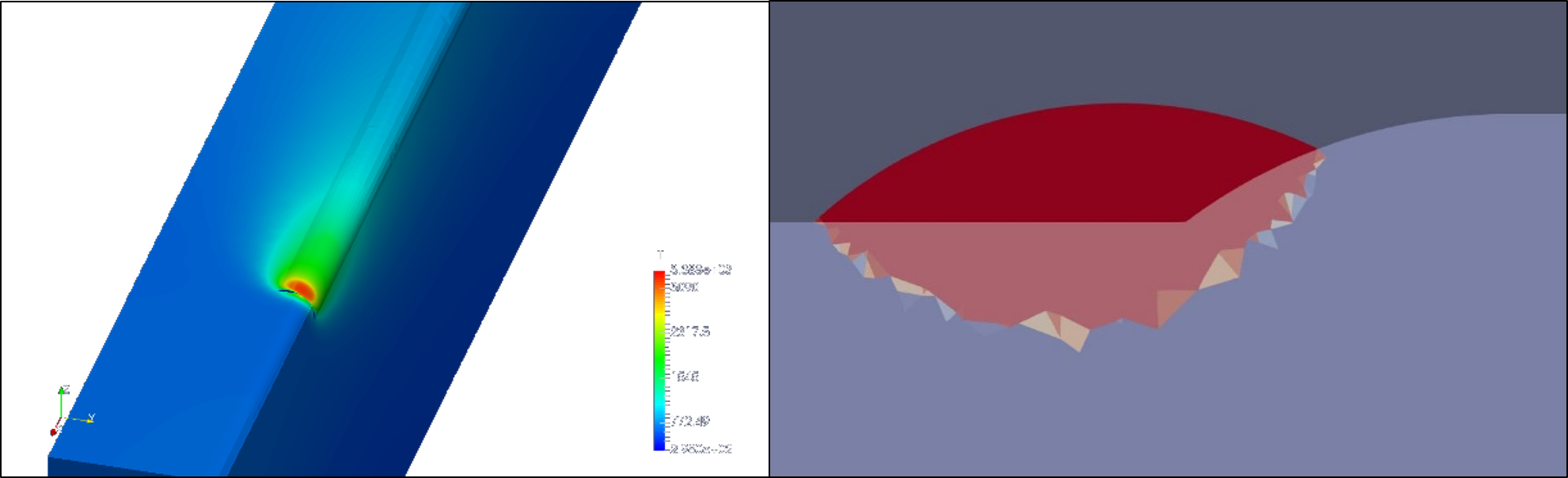

ParaGen (Parameter Generation) is thermal-fluid flow simulation software used to develop a detailed understanding of the deposition of individual tracks in the powder bed and blown powder metal additive manufacturing processes. ParaGen models track geometry, temperature, melt-pool solidification, fluid flow, and key dimensionless parameters for additive track deposition. Users can view a 3D image of the track and substrate deposited under specific parameters. With this information, users can determine if the selected parameters are suitable for a specific part. ParaGen is a quick and cost-effective alternative to experimental testing.

ParaGen solves the Navier-Stokes equations for a steady-state process. This simulation takes into account the various characteristics of the machine process to enable a detailed analysis of the deposition. It employs an automated iteration process that hones in on detailed track deposition data.

Features

- Intuitive input files

- Visualization data for 3D thermal and fluid flow in the melt pool

- Generates 3D distribution of solidification parameters

- Generates track geometry as a function of deposition parameters

- Generates dimensionless parameters to represent the melt-pool, thermal-fluid behavior (Reynolds, Stephan, Capillary, Bond, and Marangoni)

Benefits

- More cost and time efficient than experimental testing

- Hands-off automated simulation

- Simulation results help predict and mitigate build defects

- Quick simulation time (typically less than 2 hours)

Categories

- No categories

Contact Us: (937) 431-5100

Contact Us: (937) 431-5100